-

- Aqua HiFi

- Artesania Audio

- AudioQuest

- AURENDER

- Block Audio

- Boulder

- Bowers & Wilkins

- Classe Audio

- Clarisys Audio

- Constellation Audio

- Critical Mass Systems

- ENLEUM

- Esoteric

- IsoAcoustics

- Kuzma

- LUMIN

- Magico

- MSB Technology

- MBL Audio

- Nordost

- PASS LABS

- Quadraspire

- Rega

- Shunyata Research

- Stein Music

- STENHEIM

- Trinnov

- VAC Audio

- Vicoustic

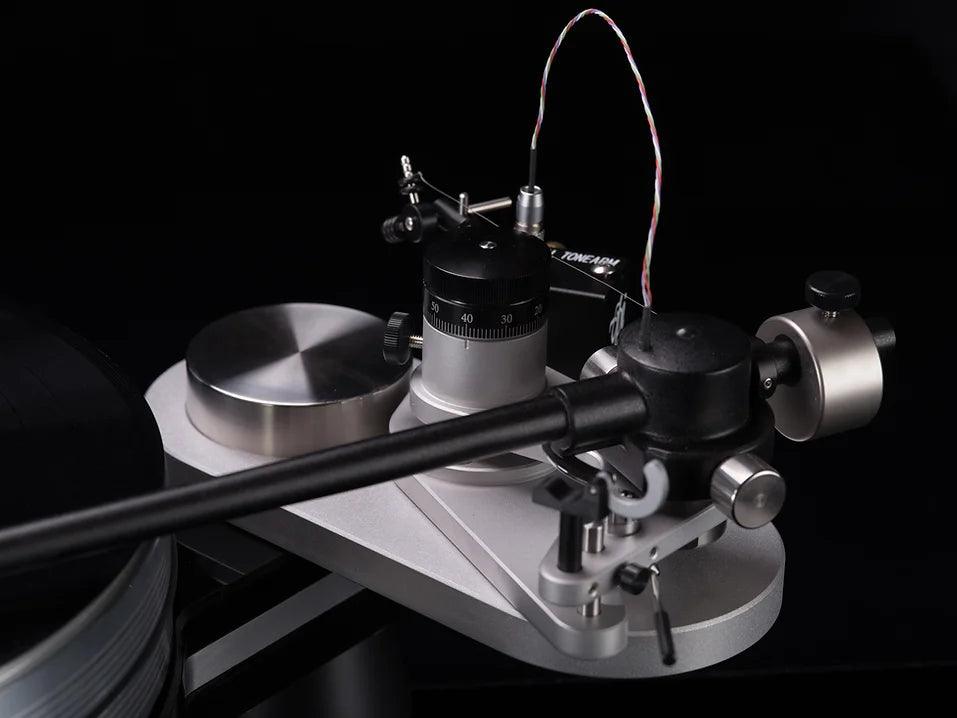

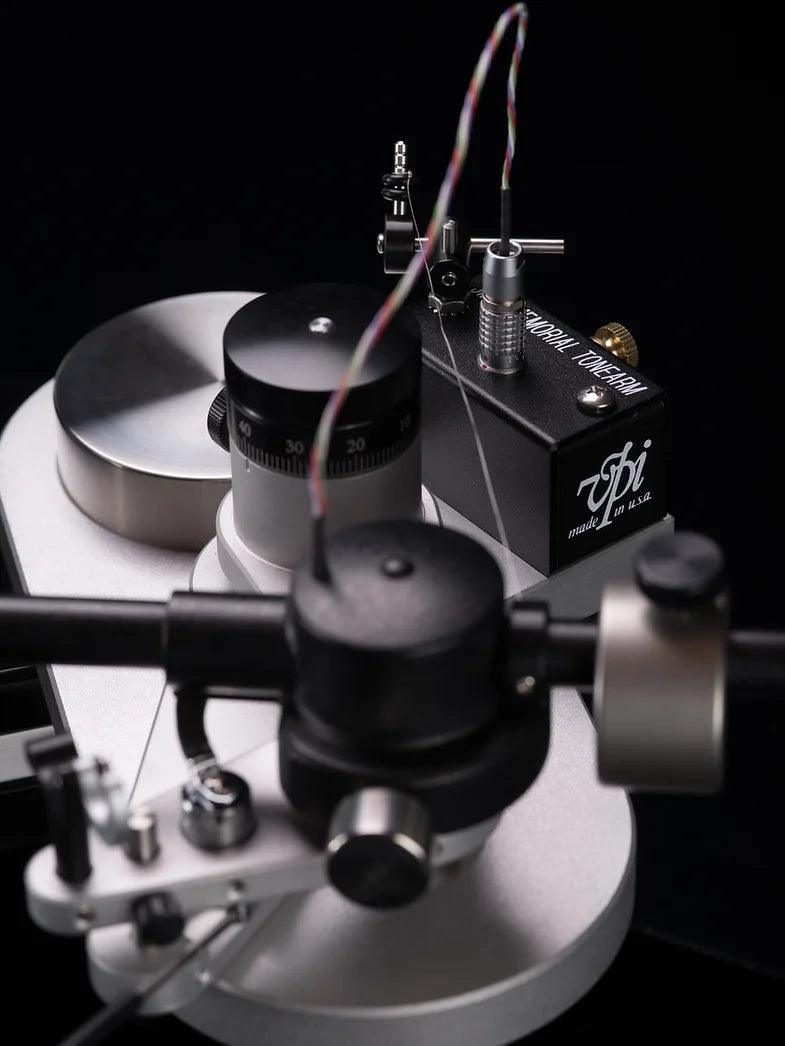

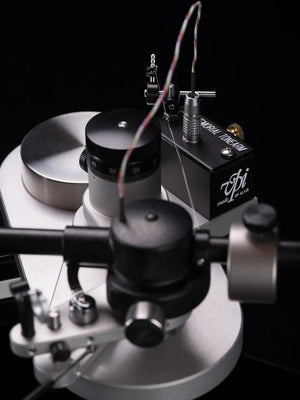

- VPI Industries

- Wireworld

-

- Login